About ELIO Stationery

Transforming moments into timeless keepsakes through premium photo album manufacturing excellence. From our humble beginnings in 2015 to serving 20+ countries worldwide, discover our journey of innovation and quality.

Our Development Journey

From OEM producer to global leader, discover how ELIO transformed the photo album manufacturing landscape through innovation and dedication.

Foundation Era

Founded as OEM producer with systematic production line, offering services for major photo album factories.

Growth Phase

Expanded machinery and developed direct international orders. Became leading album producer in Zhejiang.

Global Expansion

Established international business department. Long-term partnerships with Michaels and Kmart launched.

Future Ready

30 machines, 20+ countries served, FSC certified with BSCI management system implementation.

Key Milestones

Significant achievements that shaped our journey to becoming a trusted global partner in photo album manufacturing.

Photo Album Factory Established

Founded in Yiwu, China with focus on OEM production and systematic manufacturing processes.

ELIO International Launch

Established dedicated overseas business division, marking our entry into global markets.

Major Retail Partnerships

Secured long-term cooperation agreements with Michaels and Kmart, expanding our reach significantly.

Recent Equipment Upgrades

Our Services

Comprehensive photo album manufacturing solutions backed by years of expertise and cutting-edge technology.

Comprehensive Order Planning

Complete order optimization and planning services to ensure efficient production and timely delivery.

- Production scheduling

- Quality control integration

Photo Album Expertise

Nearly two decades of specialized experience in photo album manufacturing since 2005.

- Wedding albums

- Baby & travel albums

- Scrapbooks

Reliable Delivery

On-time delivery guarantee with comprehensive after-sales service support.

- 15 containers monthly capacity

- Global shipping network

Perfect Partner For

Stationery Wholesalers

& Importers seeking reliable supply chains

Wedding Photography

Studios requiring premium album solutions

Retail Chains

& Supermarkets with volume requirements

Trusted by Leading Brands

Partnering with industry leaders across retail, crafts, and stationery sectors worldwide

Our Certifications

Quality and sustainability certifications that guarantee excellence

FSC Certification

Forest Stewardship Council certified sustainable materials

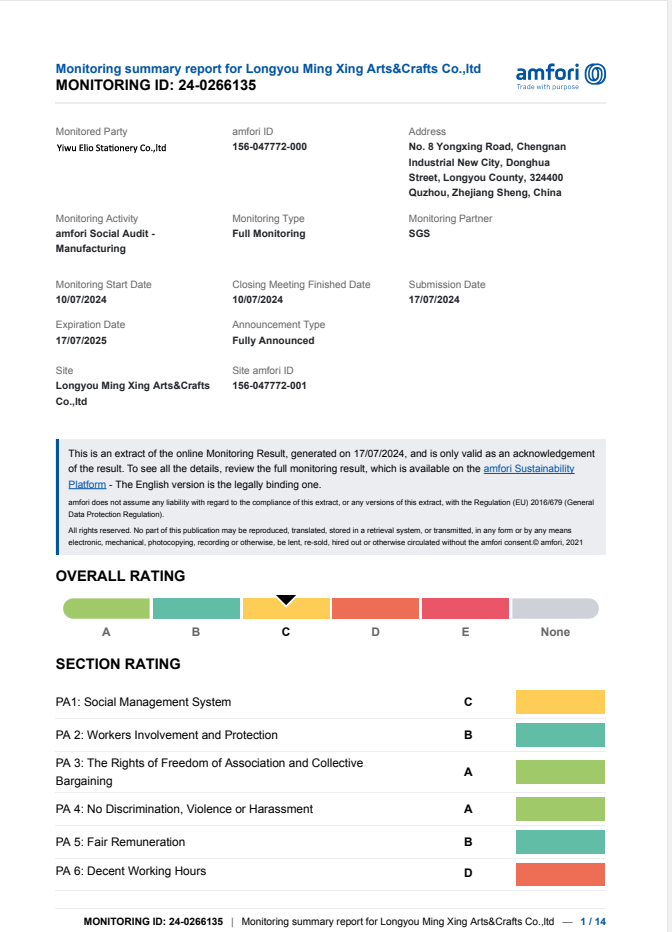

BSCI Certification

Business Social Compliance Initiative management system

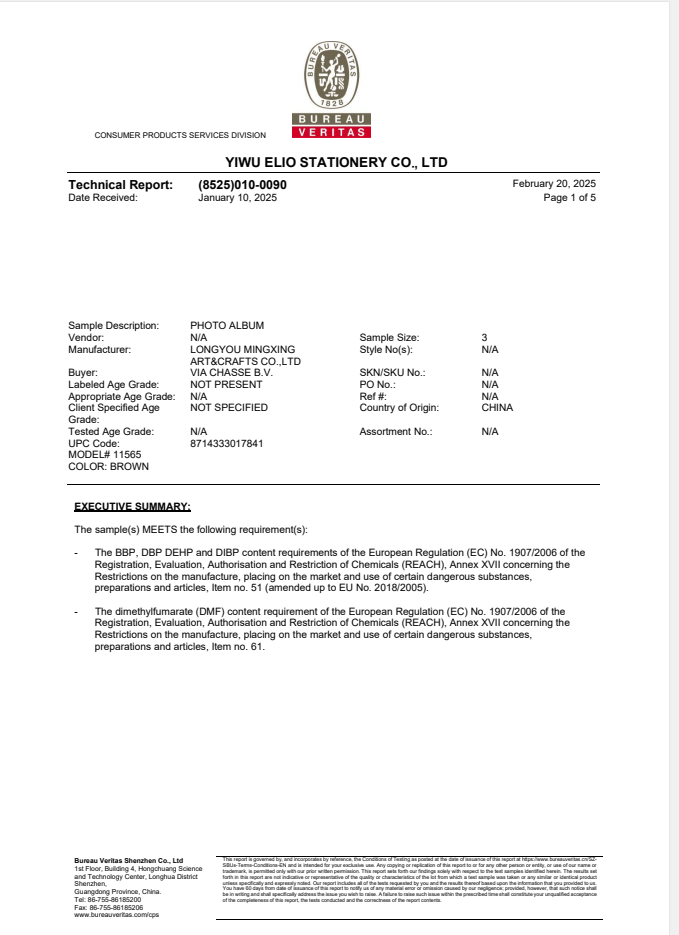

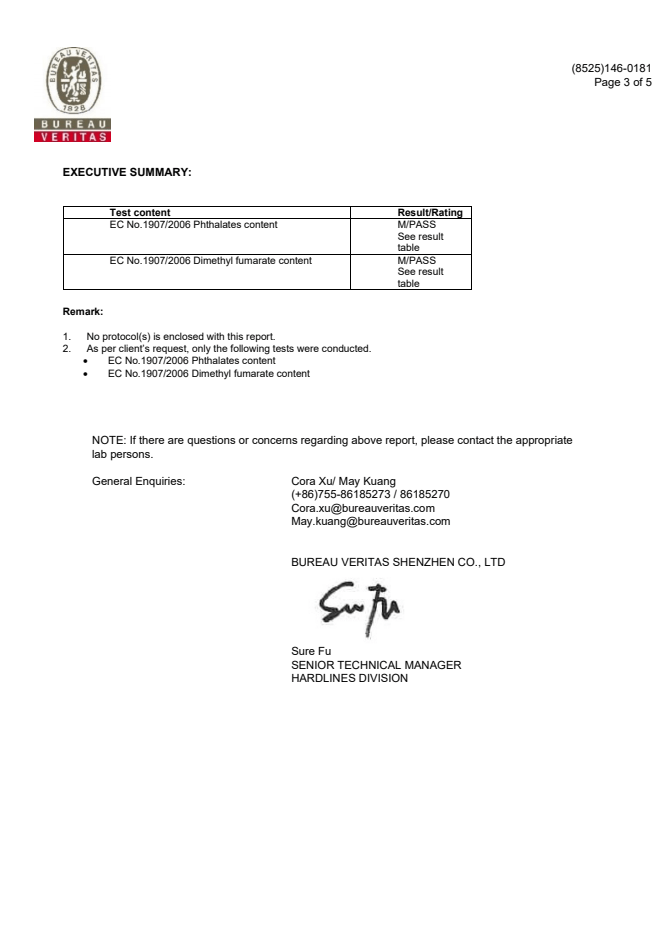

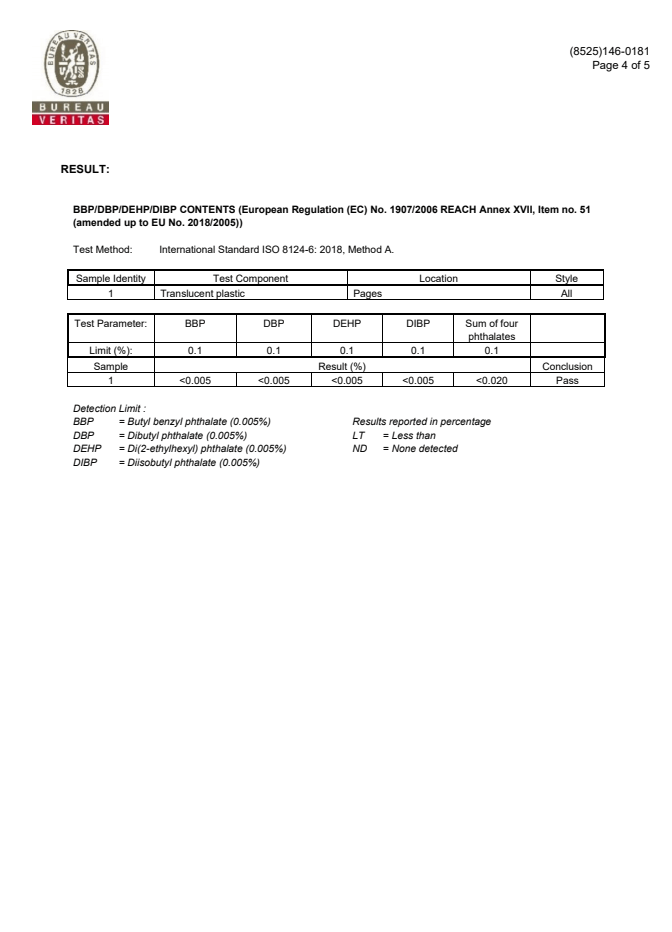

REACH Compliance

European chemical safety regulation compliance

Test Report

European Chemical safety regulation compliance

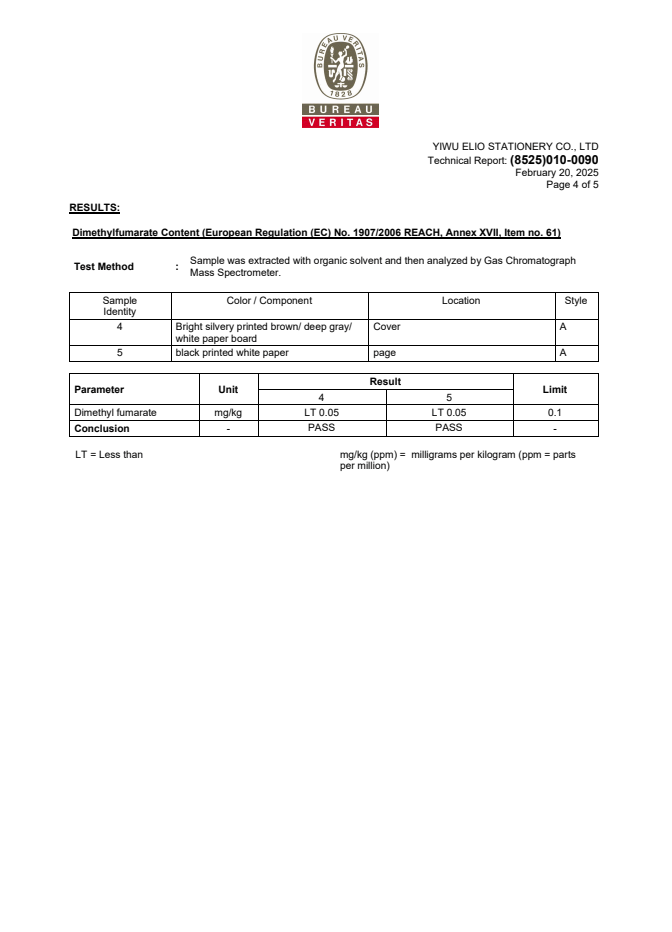

Test Report

European Chemical Safety regulation certification

CE Marking

European conformity assessment certification